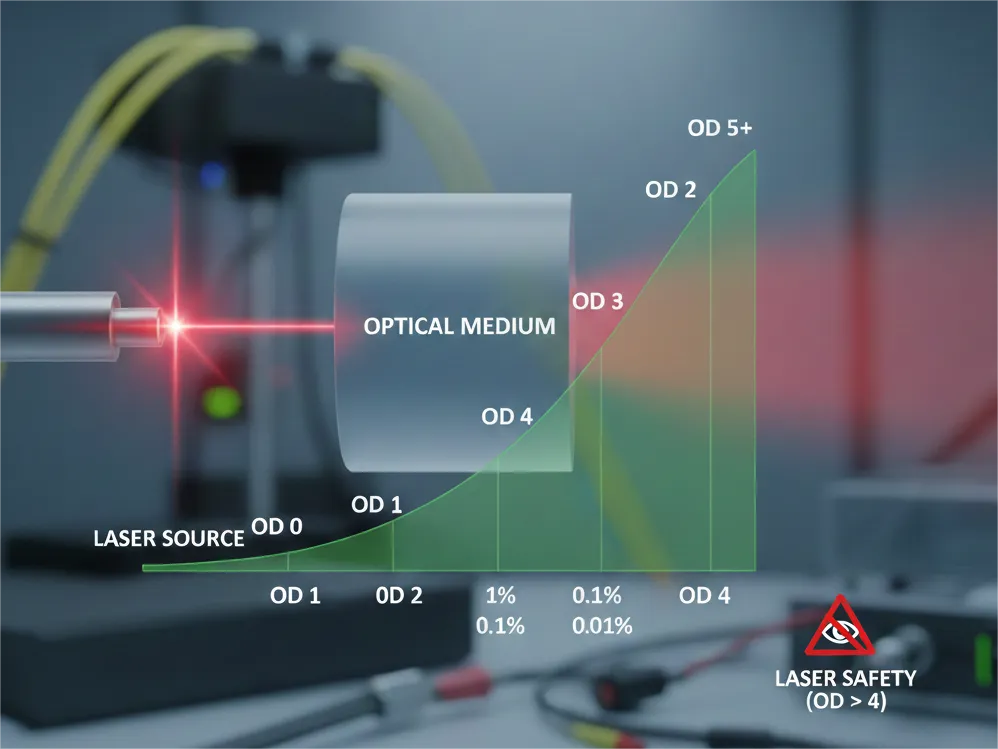

Optical density (OD) is a critical logarithmic metric that quantifies how much light an optical medium, filter, or component attenuates. Failing to understand and correctly calculate OD can lead to severe equipment damage or devastating laser eye injury. This comprehensive guide moves beyond basic definitions. We will explore the mathematical foundation of the OD scale, explain its vital application in high-power fiber optic systems, and show how PHILISUN uses precise OD verification to guarantee the safety and performance of its laser and fiber components.

Optical Density Defined: Why OD Uses a Logarithmic Scale

Optical Density (OD) is a measure of the light-stopping power of a material. Unlike simple transmittance, OD is expressed on a logarithmic scale (base 10). This scale is essential because it allows engineers to easily manage huge dynamic ranges in light power—from picowatts in communication signals to kilowatts in industrial lasers.

If a filter has an OD of 1.0, it transmits 10% of the light. An OD of 3.0 transmits 0.1% of the light. The benefit of the logarithmic scale is evident when comparing filters: two filters, each with an OD of 3.0, when stacked, have a combined OD of 6.0, not 9.0. This corresponds to a light transmission of just 0.0001%.

OD Formula Explained: How to Convert Transmittance (T) to OD Value

The mathematical relationship between optical density (OD) and transmittance (T) is defined by the following formula:

OD = -log10(T)

Where:

- T (Transmittance) is the ratio of output light power (Pout) to input light power (Pin), or T = Pout/ Pin.

- The negative sign ensures that as transmittance decreases, the OD value increases.

| Optical Density (OD) | Transmittance (T) | Percentage Transmitted | Attenuation Factor |

| 1.0 | 0.1 | 10% | 101 |

| 3.0 | 0.001 | 0.1% | 103 |

| 6.0 | 0.000001 | 0.0001% | 106 |

Why is High Optical Density Essential for Laser Safety?

Laser safety is the most critical application of optical density. OD values are used to specify the minimum required protection level for laser safety eyewear (goggles) and machine enclosures. The required OD must be high enough to reduce the beam’s intensity below the Maximum Permissible Exposure (MPE) level for the specific laser wavelength and power.

How Do You Choose the Correct OD for Your Laser Wavelength?

Choosing the correct OD involves three steps:

- Identify the Laser: Determine the wavelength (λ) and maximum output power (Pmax) of the laser source.

- Determine MPE: Consult safety standards (e.g., ANSI Z136.1) to find the MPE for that wavelength.

- Calculate Required OD: Use the laser’s power and the MPE to calculate the minimum OD required to reduce the beam power below MPE. Laser goggles are often labeled with an OD rating that is only valid for a specific wavelength range.

OD in Fiber Optics: Controlling Power and Preventing Saturation

In fiber optic communication and testing, OD is directly related to attenuation. Fiber optic attenuators are passive components used to intentionally reduce the power of an optical signal. This is done for two primary reasons:

- Preventing Receiver Saturation: High-power transmitters can overwhelm and damage sensitive receivers (e.g., Optical Power Meters or network transceivers).

- Balancing Links: Ensuring all channels in a dense wavelength division multiplexing (DWDM) system arrive at the receiver with equal power levels.

How PHILISUN Verifies Precision in Fixed Fiber Optic Attenuators

Fixed fiber optic attenuators, often used to precisely manage power levels, rely on materials engineered to provide a specific OD value at the operating wavelength (e.g., 1550 nm). PHILISUN employs advanced spectrophotometric testing to verify that every attenuator meets its specified attenuation tolerance. We ensure that a 3 dB attenuator (equivalent to an OD of 0.3) consistently reduces power by exactly 50% across the operating spectrum. This precision is critical for maintaining link budget integrity in high-speed, long-distance communication systems.

Measuring OD: The Role of Spectrophotometers and Densitometers

Optical density is measured using specialized instruments. The most common tool is the spectrophotometer, which measures light intensity before and after it passes through a sample.

What is the Difference Between OD and Attenuation in Decibels (dB)?

While both OD and attenuation (measured in decibels, dB) quantify light reduction, they are used in different contexts and related by a simple factor:

Attenuation (dB) = 10 × OD

- OD is primarily used in non-linear applications like laser safety and filtration. It is based on the log10 of intensity.

- dB is the standard metric used in telecommunications (fiber optics) to describe link loss or gain, based on 10 log10(Pout/Pin).

For example, an OD of 3.0 corresponds to an attenuation of 30 dB.

PHILISUN’s Commitment to Certified OD Performance

High-reliability applications, whether in industrial lasers or high-power DWDM systems, demand components with meticulously certified OD values. PHILISUN maintains a rigorous quality assurance protocol. We test our components—including custom filters, MPO patch cables, and variable attenuators—at specified wavelengths to guarantee their exact OD performance. This commitment to precision eliminates the guesswork for our clients, ensuring that safety barriers provide adequate protection and that network components perform as expected under extreme power conditions.

Conclusion

Optical density is far more than a technical curiosity; it is the fundamental measurement that dictates the safety, precision, and reliability of virtually every optical system. From protecting human eyes from powerful lasers to balancing the power levels in a complex fiber network, understanding the OD scale is paramount.

If your application demands precise light control, whether you need components with high OD for safety or specific OD values for link balancing, do not compromise on accuracy.

Partner with PHILISUN for verified, high-precision optical components. Contact our engineering team today for specialized quotes on fiber optic attenuators and custom OD-certified optical modules.