A fiber jumper, or patch cable, is the single most vulnerable link in your network. Low-quality jumpers introduce high insertion loss (IL) and poor return loss (RL), leading to costly network errors, especially at 10G+. This comprehensive guide breaks down the seven critical specifications you must verify before buying. We provide a quality checklist and show how PHILISUN‘s rigorous factory testing ensures every jumper delivers minimal attenuation, guaranteeing the long-term reliability and performance of your mission-critical infrastructure.

Connector Loss: Why Insertion Loss (IL) is the #1 Metric

Insertion Loss (IL) is the amount of signal power lost when the light passes through a connector. It is measured in decibels (dB). In high-speed networks (40G, 100G, and above), the total link budget—the maximum allowable loss across the entire channel—is extremely tight. A high IL in a fiber jumper can quickly consume this budget, leading to intermittent signal failure or reduced transmission distance.

What is the Maximum Acceptable IL for Single-Mode Fiber Jumpers?

Industry standards dictate that a typical connector pair (e.g., LC-to-LC) should have an IL no greater than 0.75 dB. However, in modern data centers, this is often too high.

| Connector Type | Acceptable IL Standard (General) | Recommended IL (High-Performance) |

| Standard Duplex (LC/SC) | ≤ 0.30 dB | ≤ 0.15 dB |

| MPO/MTP (Standard) | ≤ 0.75 dB | ≤ 0.35 dB (Ultra-Low Loss, ULL) |

High-performance suppliers like PHILISUN specialize in Ultra-Low Loss (ULL) components, ensuring IL values are consistently below 0.2 dB for duplex connectors to maintain robust link integrity.

Reflection: Understanding the Importance of High Return Loss (RL)

Return Loss (RL), also measured in dB, is the amount of light reflected back toward the source. High RL (meaning very little light is reflected) is crucial because reflected light causes interference (noise) that corrupts the signal. This is particularly problematic in single-mode systems that operate with high optical power.

UPC vs. APC Polish: Which Offers Better Return Loss Performance?

The end-face polish of a fiber jumper connector determines its RL performance:

| Polish Type | RL Performance | End-Face Angle | Best Application |

| UPC (Ultra Physical Contact) | ≥ 50 dB | 0°(flat) | Multi-mode, some single-mode |

| APC (Angled Physical Contact) | ≥ 60 dB | 8° (angled) | Single-Mode, High-Speed, DWDM |

For all single-mode, high-bandwidth applications, the APC polish is mandatory due to its superior RL performance (≥ 60 dB), which virtually eliminates back reflection.

Mode Selection: Single-Mode vs. Multi-Mode Fiber Jumper

Selecting the correct fiber type within the fiber jumper is dependent on the distance and bandwidth required.

When Must You Use OS2 (Single-Mode) for Data Center Interconnects?

- Multi-Mode (OM3/OM4): Used for short-distance, high-bandwidth connections (up to 300 meters for 10G) within a single data center or floor. It uses cheaper VCSEL lasers.

- Single-Mode (OS2): Mandatory for campus backbones, long-haul connections (over 550 meters), and all high-speed Dense Wavelength Division Multiplexing (DWDM) links. Its superior bandwidth capacity makes it the default choice for future-proofing your network core.

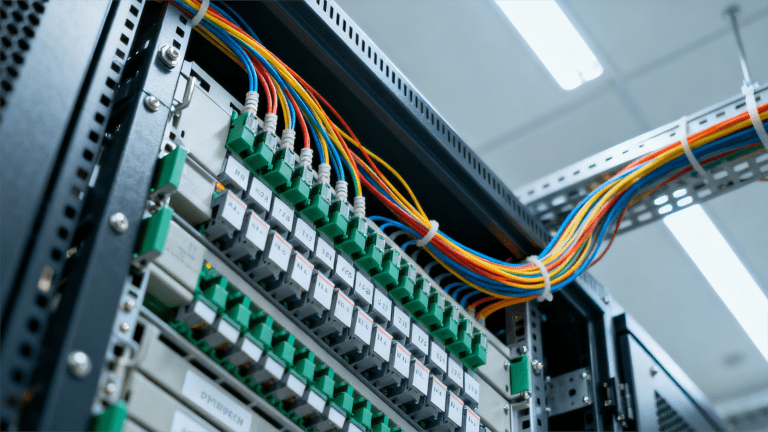

Connector Density: Choosing Simplex, Duplex, or MPO Jumper

The physical form factor of the fiber jumper dictates the density and type of port it can connect to.

| Type | Fiber Count | Application |

| Simplex | 1 | Single-way data, specialized sensors |

| Duplex | 2 | Standard 1G/10G/40G links (Tx/Rx pair) |

| MPO/MTP | 8, 12, 24, 48 | High-density 400G/800G switch-to-switch links |

How High-Density MPO Jumpers Simplify Rack Connectivity

MPO (Multi-fiber Push On) connectors consolidate multiple fiber strands (up to 24) into a single, compact connector. This is essential for 400G deployments, where a single QSFP-DD port requires 16 fibers (8 Tx, 8 Rx). Using MPO fiber jumpers dramatically reduces cable bulk and installation complexity inside the rack.

PHILISUN’s Quality Vetting Process for Low-Loss Fiber Jumpers

At PHILISUN, we recognize that even the best network equipment is bottlenecked by the quality of its patch cables. Our commitment is to eliminate component-level errors before they reach your data center.

We implement a rigorous, 100% factory testing protocol for every single fiber jumper we produce. This includes:

- IL/RL Verification: Every connector pair is individually tested with reference-grade equipment to guarantee performance above industry standards (typically ≤ 0.15 dB for LC/SC and ULL MPO).

- End-Face Inspection: Every ferrule is inspected under a microscope to confirm the polish (UPC or APC) is flawless and free of defects, ensuring optimal physical contact and minimal back reflection.

- Custom Loss Reports: We provide a dedicated, serial-numbered test report for every custom fiber jumper or MPO assembly, giving you verifiable proof of quality to meet your link budget requirements.

Fire Safety: Selecting the Right Cable Jacket (LSZH vs. Plenum)

Cable jacket material is critical for compliance and safety within buildings.

- Plenum: Designed for air-handling spaces (plenum ceilings or floors). When burned, it releases minimal smoke and flame. Required by code in many areas.

- LSZH (Low Smoke Zero Halogen): The preferred standard in Europe and in tightly packed data centers. If burned, LSZH jackets release minimal corrosive or toxic fumes, protecting sensitive electronics and personnel.

Choosing the right fiber jumper jacket ensures compliance and protects your critical hardware from potential smoke damage during a fire event.

Conclusion

Choosing a fiber jumper is a decision that directly impacts your network’s long-term performance and stability. Focusing solely on the lowest price often results in jumpers with poor IL and RL, leading to costly re-testing and component replacement down the line. By prioritizing the seven specifications outlined here—especially low Insertion Loss and high Return Loss—you ensure a resilient and high-performing link. PHILISUN provides the quality assurance and precise, certified low-loss jumpers necessary to future-proof your network.

Ready to eliminate link budget errors with verifiable, factory-tested fiber jumpers? Contact PHILISUN today to discuss your ULL single-mode and MPO assembly needs.