The unrelenting demand for bandwidth is forcing data centers and large enterprises to adopt high-density fiber infrastructure using MPO connectors. However, the commercial decision hinges on choosing between the generic MPO connector and the enhanced, patented MTP® connector. While MTP connectors carry a higher upfront cost, a true assessment requires calculating the long-term Return on Investment (ROI) based on performance, durability, and maintenance. This analysis breaks down the technical differences that ultimately define your network’s long-term profitability and reliability.

Understanding the Foundation: MPO vs MTP Defined

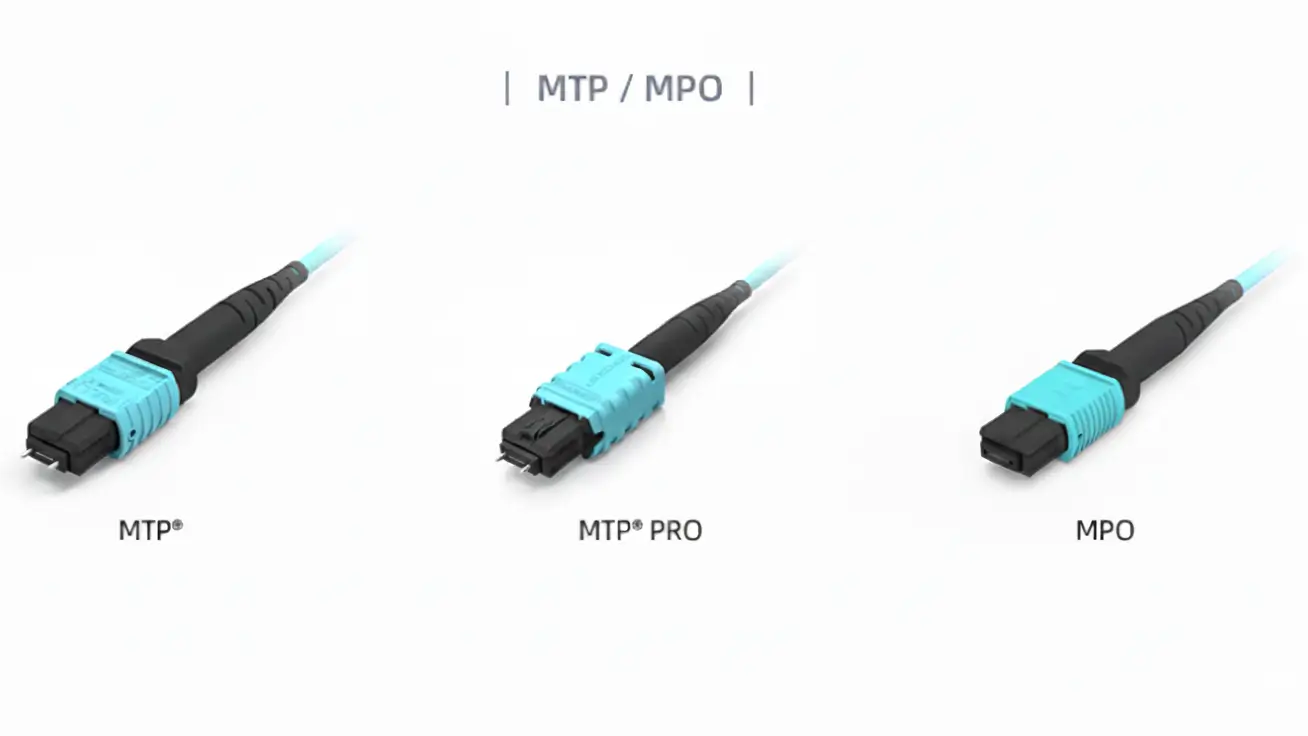

Though often used interchangeably, MPO is the industry standard (IEC 61754-7), and MTP is a specialized, high-performance variant of that standard, registered by US Conec.

The MPO Standard: Density and Compatibility

The MPO (Multi-fiber Push-On) connector is the foundational technology that terminates multiple fibers (typically 12 or 24) into one ferrule. Its primary function is to consolidate numerous simplex or duplex connections into a compact, pre-terminated, plug-and-play assembly, drastically reducing installation time and cable bulk.

MTP Enhancements for Superior Mechanics

The MTP connector features multiple engineered improvements over generic MPO, all designed to ensure better physical contact and performance stability:

- Floating Ferrule: The MTP ferrule is designed to “float” within the housing, allowing it to maintain physical contact across the mated pair even under applied load or side strain, which significantly reduces signal instability.

- Elliptical Guide Pins: Instead of the sharp, chamfered pins used in generic MPO that can generate debris, MTP utilizes tightly held tolerance, elliptical stainless-steel guide pins that reduce wear and debris accumulation.

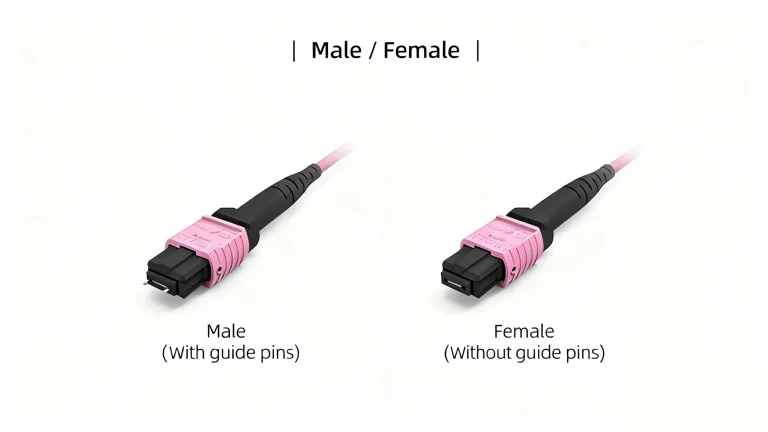

- Removable Housing: The MTP housing can be removed, allowing for field-cleaning, re-polishing, and even changing the connector gender (male/female) and polarity (Type A/B/C) on-site.

The ROI Debate: Structural Differences that Impact Cost

The structural differences translate directly into performance and longevity—the two factors that define ROI in network cabling.

Insertion Loss and Performance Stability

Insertion Loss (IL) is the most critical metric. MTP’s superior alignment mechanisms result in reliably lower IL compared to generic MPO.

| Connector Type | Typical Maximum Multimode Insertion Loss | Commercial Impact |

| Generic MPO | 0.75 dB | Tight link budgets, less room for error. |

| Standard MTP | 0.60 dB | More stable performance, greater link budget headroom. |

| MTP Elite | 0.35 dB | Ideal for 400G+ hyperscale environments. |

A lower IL is crucial for 400G and 800G deployments, allowing for longer cable runs or supporting more components in the channel before exceeding the system’s power budget.

Durability, Maintenance, and Field Serviceability

The MTP’s metal pin clamp and robust guide pins offer superior resistance to breakage during repeated mating cycles compared to plastic MPO components. Crucially, the removable housing feature enables technicians to service and clean the ferrule in the field. This capability alone can turn a damaged cable from a complete loss into a serviceable asset, dramatically reducing the Total Cost of Ownership (TCO).

Strategic Procurement: Where to Justify the MTP Premium

The decision between MTP and MPO is entirely application-driven.

Mandating MTP: Core Data Center Fabrics

- High-Speed/High-Density Links: MTP is mandatory for links supporting 400G, 800G, and future multi-terabit speeds (e.g., Spine-Leaf architectures, core switches, and critical backbone links). The MTP’s reliability is a low-cost insurance policy against expensive downtime.

- Field Flexibility: Environments requiring frequent reconfigurations, repairs, or polarity changes benefit immensely from MTP’s field-serviceability features.

When Generic MPO Is Sufficient

- Cost Optimization: MPO is a practical, cost-effective solution for less performance-sensitive areas, such as low-speed test benches, short-distance patch connections, or legacy systems where link budgets are not strained. PHILISUN provides MPO cable assemblies guaranteed to meet industry standards for these cost-optimized applications.

Conclusion

The MTP connector is a highly engineered MPO variant that delivers better mechanical and optical performance. While the upfront investment is higher, the MTP’s superior durability, lower insertion loss, and field-serviceability typically lead to a better long-term ROI in mission-critical, high-speed enterprise and cloud environments. Generic MPO remains a viable, budget-friendly option for non-critical, short-distance applications.

Ensure your network investment is protected with certified, low-loss components. Contact PHILISUN today for custom MTP and MPO cable solutions tailored to your specific performance and ROI requirements.

FAQ

- Q1: Are MTP and MPO connectors compatible?

- Yes. MTP connectors are 100% compatible with generic MPO connectors and can intermate. However, mixing them will limit the performance of the channel to the quality of the generic MPO connector.

- Q2: What is MTP Elite?

- MTP Elite is a premium version of the MTP connector featuring even tighter tolerances, achieving an insertion loss as low as $\leq 0.35 \text{ dB}$, making it essential for single-mode and hyper-scale applications.

- Q3: How does MTP help with Polarity?

- The removable housing on MTP PRO connectors allows technicians to change the MPO cable polarity (Type A/B/C) and gender in the field with a simple tool, minimizing inventory and eliminating installation errors.