The LC fiber connector (Lucent Fiber Connector) is the undisputed champion of the modern data center, owing its dominance to its small form factor and robust performance. While its miniature size is its most visible feature, the true performance of an LC connection relies on the precision engineering of its internal components, particularly the ferrule and the end-face polish. Understanding the differences between the common polish types—PC, UPC, and APC—is critical for network architects, as the wrong selection can lead to catastrophic signal loss and system failure in high-speed, long-distance links.

The Anatomy of the LC Fiber Connector

The LC fiber connector is a small form factor (SFF) connector that uses a push-and-latch mechanism, similar to a standard RJ45 copper connector, but built for optical precision.

The Precision Ferrule

The heart of the LC fiber connector is the ferrule, typically a 1.25mm ceramic cylinder. The ferrule holds the optical fiber perfectly centered and aligned. This 1.25mm size is half the size of the SC connector’s 2.5mm ferrule, which is why the LC is known for its high-density capabilities. The precision with which the fiber is seated and polished inside this ferrule dictates the connector’s performance.

Simplex LC Connector (One Fiber)

A Simplex LC connector is the basic unit of the design, housing a single fiber strand within its body. Simplex connectors are used when only one-way transmission is required or, more commonly, when deployed with Bi-directional (BiDi) transceivers. BiDi optics utilize two different wavelengths (e.g., 1310nm and 1550nm) to send and receive data simultaneously over a single fiber, reducing the total fiber count needed.

Duplex LC Connector (Two Fibers)

The Duplex LC connector is the most common configuration for standard networking. It consists of two Simplex LC connectors joined together by a plastic clip or bridge. This assembly ensures that the Transmit (Tx) fiber and the Receive (Rx) fiber are maintained in the correct polarity. Duplex LCs are essential for connecting two-way transceiver interfaces like SFP+ and QSFP modules (via breakout harnesses).

Insertion Loss and Return Loss

Two critical metrics define connector quality:

- Insertion Loss (IL): The power lost when light passes through the connector pair. Good quality LC connectors should aim for an IL of less than 0.25 dB.

- Return Loss (RL): The power reflected back toward the source. High RL can destabilize lasers, especially in Single Mode systems. This is directly controlled by the end-face polish. PHILISUN rigorously tests all of its LC connectors for optimal IL and RL before deployment.

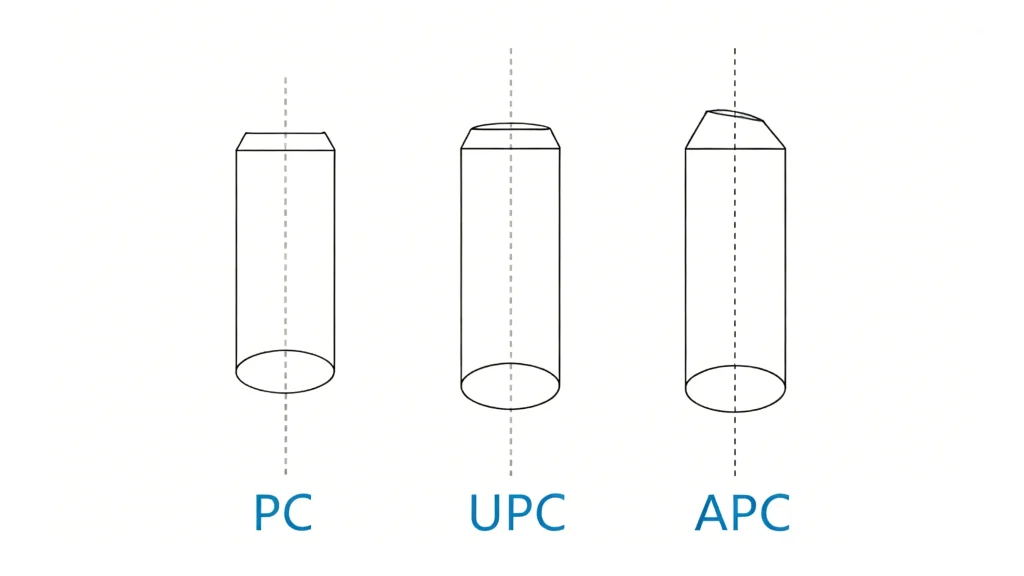

Understanding Fiber End-Face Polish (PC, UPC, APC)

The polish applied to the ferrule’s tip is the most critical factor determining the connector’s suitability for different network applications.

PC (Physical Contact)

The earliest polish type, where the fiber ends are spherically polished to ensure they touch tightly, minimizing the air gap. PC polish is now largely obsolete, having been replaced by UPC.

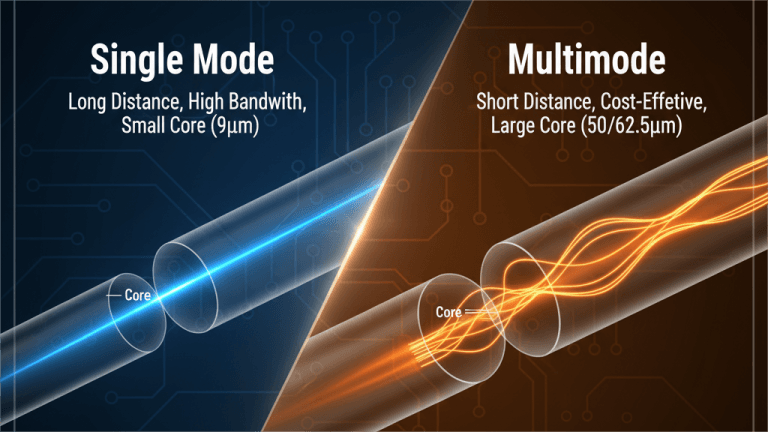

UPC (Ultra Physical Contact)

UPC polish represents a more refined, extended polishing of the convex curve. This results in an incredibly flat and smooth surface finish, achieving superior Return Loss compared to PC.

- Typical RL: > 50 dB

- Application: UPC is the standard polish for Multimode fiber (OM3, OM4, OM5) and is commonly used for short-reach Single Mode links in data centers. UPC connectors are easily identified by their blue housing or strain relief boot.

APC (Angled Physical Contact)

APC polish is the highest standard polish, featuring an 8-degree angle applied to the fiber end face. This angle ensures that any reflected light is directed into the cladding (the outer glass layer), preventing it from traveling back toward the source laser. This achieves the lowest possible back-reflection.

- Typical RL: > 65 dB

- Application: APC is mandatory for all long-haul, high-wavelength Single Mode applications (e.g., 1550nm) and WDM (Wavelength Division Multiplexing) systems where back-reflection is catastrophic. APC connectors are identified by their green housing or strain relief boot.

Key Properties and Selection Criteria

Choosing the right LC fiber connector depends entirely on your link specifications.

How to Choose the Right Polish Type

For most enterprise LAN and data center architects, the rule is simple: use UPC (blue) for Multimode and short-reach Single Mode, and use APC (green) for all long-haul Single Mode and DCI applications. Selecting the correct polish is paramount to ensuring laser stability.

Why Is LC Compatiblity Important

LC connectors are compatible with transceivers ranging from 1G to 400G and are necessary for break-out cables from high-density MPO/MTP interfaces. The precision and consistent quality of the connector body and ferrule are critical for these high-speed applications. PHILISUN guarantees that all its LC connectors, whether UPC or APC, meet IEC standards for geometry and end-face inspection.

Conclusion

The LC connector remains the industry standard due to its 1.25mm ferrule, which enables high-density patching. The final choice between UPC and APC polish is a function of the network’s complexity and distance: UPC is generally used for Multimode and short Single Mode links, while APC is mandatory for long-distance and WDM systems to mitigate reflective light.

To learn more about our innovative fiber optic technologies and high-speed networking solutions, contact PHILISUN Experts Today.

FAQ

Q1: What does LC stand for?

A1: LC stands for Lucent Connector, named after Lucent Technologies, which developed it.

Q2: What is the diameter of the LC ferrule?

A2: The LC uses a 1.25mm ceramic ferrule.

Q3: How can I visually identify an APC connector?

A3: APC connectors are typically identified by their green strain relief boot or housing.

Q4: Which polish type provides the best Return Loss (RL)?

A4: APC (Angled Physical Contact) provides the best Return Loss, typically > 65 dB.

Q5: Is the LC connector compatible with 400G?

A5: Yes, LC connectors are used extensively as the duplex interface on 400G and 800G breakout cables (e.g., 400G-DR4 breaks out to 8x 50G-SFP56 LCs).