A Light Source and Power Meter only tell you if a fiber link fails; the Optical Time Domain Reflectometer (OTDR) tells you why and where. As the essential diagnostic tool, the OTDR characterizes, tests, and locates faults in fiber optic cables with radar-like precision. This comprehensive guide details the OTDR’s operating principles, key measurements, and practical application. Master the OTDR to protect your fiber investment and ensure successful Tier 2 certification.

What is an OTDR? Defining the Fiber Optic Radar

The “Time Domain” Concept: Why Timing is Everything

The OTDR is often compared to electronic radar because it operates on the same principle: sending a pulse and analyzing the time it takes for the return signal to determine distance. This time-domain analysis is foundational. The OTDR launches an optical pulse into the fiber and then measures the weak light signal that is reflected or scattered back to the detector over time. By combining the measured light intensity with the time delay, the instrument generates a graphical map of the fiber, establishing the OTDR as the only tool capable of providing a full fiber map and serving as the foundation for Tier 2 Fiber Certification.

Why Use an OTDR Instead of a Power Meter?

While a Light Source and Power Meter is necessary for Tier 1 certification, these tools only measure the Total Insertion Loss of the link, giving a simple pass/fail result. The OTDR provides a granular level of detail that is crucial for troubleshooting and quality control. The OTDR measures the individual loss and location of every single component within the link, such as connectors, splices, and breaks. Therefore, both Tier 1 and Tier 2 testing are complementary and necessary for full fiber characterization.

How Does the OTDR Work? The Science of Backscatter

The OTDR’s functionality relies on interpreting two distinct forms of light return, known collectively as backscatter.

Analyzing the Signal: The Dual Physics of Loss Detection

The OTDR utilizes two separate physical phenomena to map the cable:

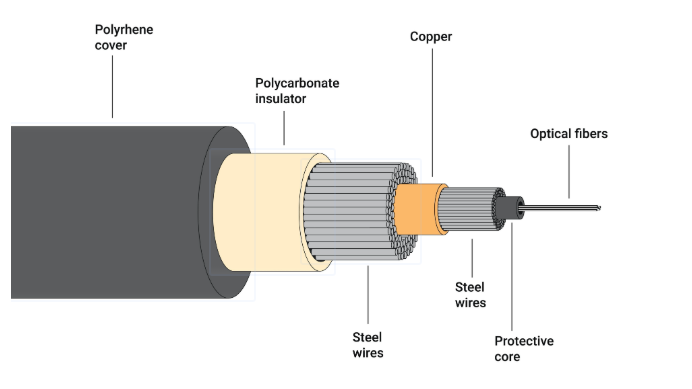

- Rayleigh Scattering: This is the continuous, microscopic back-reflection of light caused by tiny compositional variations within the fiber’s glass structure. The OTDR uses the smooth, downward decay of this continuous signal to calculate the fiber’s Attenuation (loss per kilometer) and total Length.

- Fresnel Reflection: This is the large, distinct reflection of light that occurs at non-continuous points where the refractive index changes, such as at a connector interface or a fiber break. The OTDR uses the magnitude (height) of these sharp peaks to measure the Reflectance (return loss) and the time delay to measure the Distance.

Calculating Distance: The Index of Refraction (IOR) Factor

To translate the measured time into an accurate physical distance, the OTDR must be programmed with the fiber’s specific Index of Refraction (IOR), sometimes called the Group Index.

- The IOR defines the speed at which light travels through the core of the specific fiber being tested.

- Unique Flair: If the incorrect IOR value is entered, the calculated distances to all events, including faults, will be inaccurate, potentially leading to wasted time and resources when locating a break.

Ensuring the integrity of your optical components is vital for accurate testing, which is why PHILISUN provides detailed specifications, including IOR values, for all its fiber types.

How Do You Read the OTDR Trace? Interpreting Key Trace Events

The OTDR trace is a graph displaying optical power (in dB) on the vertical axis against distance (in km) on the horizontal axis.

What Are the Non-Reflective Events on the Trace?

These events cause a downward step in the trace but lack a sharp reflective peak, indicating power loss.

- Fusion Splices: Appear as a sharp vertical drop in the trace, indicating the loss introduced by the permanent joint (0.1dB is desirable).

- Macro-bends: Gradual dips in the trace caused by the fiber exceeding its specified minimum bending radius (stress), resulting in light leakage and non-reflective loss.

- Non-Reflective Connectors: Can occur when connectors are mated using specialized index-matching gel.

What Are the Key Reflective (Fresnel) Events?

These events are characterized by distinct vertical peaks that indicate a non-continuous interface.

- Connector Pairs: Appear as distinct reflective peaks followed by a drop in signal strength (loss). The peak’s magnitude helps assess the quality of the mating interface.

- The End of Fiber: The final, largest reflective peak on the trace, which marks the total distance of the cable.

- Gainer Event: This fictional event occurs when a splice appears to have negative loss (gain). This is physically impossible and is caused by testing two fibers with different backscatter coefficients. It requires Bi-Directional Testing to calculate the accurate, averaged loss.

What Are Dead Zones and Why Do They Matter?

Dead zones are areas immediately following a reflective event where the OTDR’s detector is momentarily overloaded and blinded, preventing accurate measurement of nearby components.

- Event Dead Zone (EDZ): The minimum distance required between two reflective events for the OTDR to distinguish them as separate components.

- Attenuation Dead Zone (ADZ): The minimum distance required after a reflective event for the OTDR to accurately measure the loss of the following non-reflective event (e.g., a nearby splice).

- Dead zones are the primary reason external Launch and Receive Cables are mandatory.

How Do You Use an OTDR? Practical Setup and Optimization

Accurate, compliant OTDR testing depends entirely on correct physical setup and parameter selection.

The Golden Rule: Why Launch and Receive Cables Eliminate the Dead Zone

To measure the loss of the first and last connectors in a permanent link, external patch cords are mandatory.

- Launch Cable: This cable is connected between the OTDR and the fiber under test. It allows the powerful reflection from the OTDR’s output port to dissipate, ensuring the first connector under test falls outside the OTDR’s internal dead zone.

- Receive Cable: This cable is connected at the far end of the link. It ensures the measurement of the final connector is complete before the trace ends.

Optimizing the Test: The Pulse Width vs. Distance Trade-off

Optimizing the OTDR’s settings is critical for capturing a clean trace. The most important parameter is Pulse Width.

- The Pulse Width is a duration (e.g., 10ns, 100ns, 1µs) of the light pulse launched into the fiber.

- Trade-off: A short pulse provides the best spatial resolution and the smallest dead zone, essential for short data center links. A long pulse achieves the greatest distance (Dynamic Range) but increases the dead zone, making it ideal for long-haul telecom links. Choosing the wrong pulse width can render the test useless.

When Should You Use an OTDR? Certification and Risk Mitigation

Mandatory for Tier 2 Certification and Baseline Documentation

The OTDR is the defining tool for Tier 2 Certification. This is the process of creating a permanent, traceable fiber map detailing the loss and distance of every single component in the link. This baseline documentation is often a requirement for network warranties and is essential for:

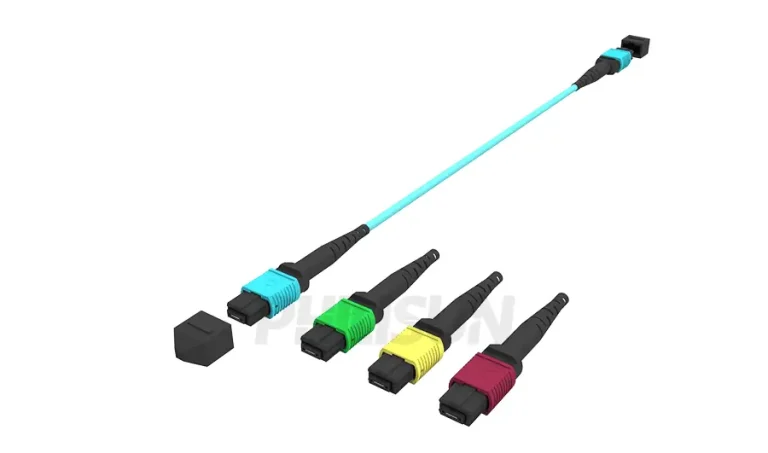

- To reliably meet this strict performance baseline, you must use high-quality, factory-tested cables. PHILISUN is committed to supplying certified, low-loss MPO and fiber jumper assemblies that guarantee a compliant OTDR baseline.

The Ultimate Tool for High-Risk Fault Location

The OTDR excels at diagnostics. Unlike Tier 1 testing, which only gives a failure notice, the OTDR provides the exact location of a fault, typically within a few meters.

- Unique Flair: This capability is crucial in high-stakes troubleshooting (e.g., a cut submarine cable or a long campus backbone break), where quickly and accurately locating the fault minimizes expensive service downtime and repair costs.

- The OTDR can also be used for Live Fiber Testing (via a 1625nm/1650nm port) to locate faults on active fibers without interrupting network traffic.

Conclusion: The Indispensable Tool for Fiber Integrity

Mastering the OTDR confirms your link quality, but reliable results depend on reliable cables. Don’t risk failing your Tier 2 test due to faulty components. Contact the PHILISUN technical team today for expert consultation on OTDR procedures and Tier 2 testing requirements, and explore our full line of factory-certified, ultra-low-loss MPO and fiber jumper solutions guaranteed to protect your network budget and pass your OTDR baseline every time.