In fiber optics, the terms “optical fiber” and “optical fiber cable” are often used interchangeably, but they represent fundamentally different things. Confusing the two can lead to significant errors in network planning and installation. The optical fiber is the delicate transmission medium, while the optical fiber cable is the rugged, complex product engineered for real-world deployment. Understanding the purpose of each component is essential for network success.

This guide clarifies the structure, application, and purchasing considerations for both.

What Exactly is a Bare Optical Fiber?

What is an Optical Fiber Used For?

- Definition: The optical fiber itself is a very thin strand of glass or plastic used to transmit data as light signals. It is the transmission medium, but not the final product.

- Key Function: Transmitting light from point A to point B with minimal attenuation (dB).

Three Essential Layers of The Fiber?

- Core: The inner glass region where light travels.

- Cladding: The layer surrounding the core that reflects light back into the core via total internal reflection.

- Primary Coating (Buffer): A thin plastic layer applied directly to the cladding for initial protection and handling.

How do SMF and MMF fibers differ?

- Single-Mode Fiber (SMF): Smaller core (≈9µm), designed for long-distance, higher bandwidth applications (e.g., 10 G and up).

- Multimode Fiber (MMF): Larger core (≈50µm or 62.5µm), used for short-distance applications within data centers and buildings.

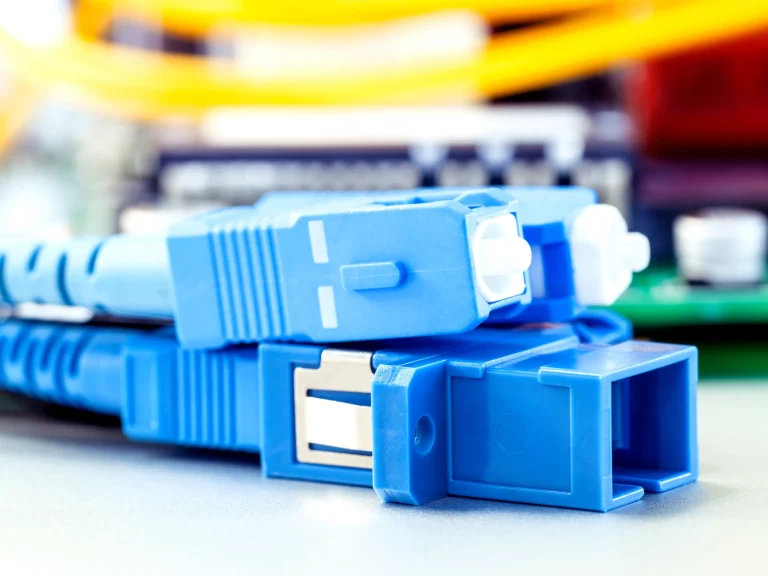

What is an Optical Fiber Cable Made Of?

What is an Optical Fiber Cable Used For?

- Definition: The optical fiber cable is the finished assembly designed to house, protect, and provide the necessary tensile strength for one or more optical fibers in a working environment.

- Key Function: Protecting the fragile optical fiber from mechanical damage (crush, bend), moisture, and temperature changes during deployment and operation.

The Main Protective Layers of A Cable

- Buffer/Sheath: The tube or layer that holds the individual fibers (e.g., loose tube or tight buffer construction).

- Strength Members: Materials (like Aramid yarn, fiberglass, or steel wires) that run parallel to the fibers to prevent the optical fiber cable from being stretched during installation.

- Outer Jacket: The final external layer is made of materials like PVC, polyethylene (PE), or LSZH, providing protection against the environment (fire, moisture, UV).

Why are the protective layers necessary for installation?

- Addressing tensile load (pulling) during installation.

- Crush and impact resistance after installation.

- Protection from environmental hazards (water, sunlight, chemicals).

Fiber vs. Cable: How Do Their Functions Compare?

What is the critical distinction between a bare fiber and a cable?

- The optical fiber is the engine that transmits the light signal.

- The optical fiber cable is the vehicle that makes the engine rugged enough to be deployed underground, pulled through ducts, or installed in plenum spaces.

Quick Comparison: Fiber vs. Cable

| Feature | Optical Fiber | Optical Fiber Cable |

| Primary Goal | Transmitting light | Protecting the fiber |

| Components | Core, Cladding, Coating | Buffer, Strength Members, Jacket, (Fibers) |

| Size | Hair-thin (≈250µm) | Much thicker (e.g., 5 mm to 20 mm) |

| Installation | Cannot be installed bare | Designed for installation in various environments |

How Does the Cable Structure Affect My Purchase Decision?

What are the common types of fiber optic cables I might need?

- Loose Tube: Ideal for outdoor, long-haul applications; fibers float freely in gel-filled tubes, providing superior water/temperature protection.

- Tight Buffer (Distribution/Breakout): Ideal for indoor, vertical runs, and short distances; each fiber has a thick buffer layer for easy termination.

- Simplex/Duplex: Simple two-fiber construction for patch cords and equipment interconnection.

How does the cable jacket affect where I can install it?

- Indoor (Safety Focused): Use jackets like Plenum (OFNP) or Riser (OFNR) to meet building fire codes, or LSZH (Low Smoke Zero Halogen) in areas with high public density.

- Outdoor (Durability Focused): Use jackets made of UV-resistant polyethylene (PE), often with Armoring (steel tape) for direct burial or aerial runs.

- For high-quality, compliant optical fiber cable solutions, trust PHILISUN to provide the appropriate construction for your specific installation environment.

Frequently Asked Questions (FAQ)

Q1: Can I install a bare optical fiber without a cable jacket?

- A: Absolutely not. A bare optical fiber is extremely fragile and susceptible to micro-bends, which cause signal loss. The cable assembly is required to provide crush resistance, tensile strength, and environmental protection, as well as to meet fire and safety codes for premises wiring.

Q2: Why are fiber optic cables often so much thicker than the fiber itself?

- A: The majority of the cable’s thickness comes from the protective elements: the buffer tubes, the aramid yarn or fiberglass strength members, and the thick outer jacket. These layers are essential to prevent damage to the hair-thin fiber inside during pulling, crushing, or exposure to moisture.

Q3: How do I know if the cable I need contains Single-Mode or Multimode fiber?

- A: This is usually indicated by the cable jacket color (per TIA standards) and markings: Yellow jackets typically indicate Single-Mode Fiber (OS2). Aqua or Violet jackets typically indicate Multimode Fiber (OM3, OM4, or OM5).

Q4: What is the primary difference between a “Loose Tube” and a “Tight Buffer” cable?

- A: This refers to the cable’s internal structure. Loose Tube cables have fibers ‘floating’ inside gel-filled tubes, providing superior outdoor environmental protection. Tight Buffer cables have a thick, protective plastic coating around each fiber, making them better for indoor applications and easier to terminate directly.

Q5: Is the cable jacket color standardized?

- A: Yes. TIA standards provide color codes. For instance, Yellow is standard for Single-Mode, Orange for Multimode OM1/OM2, and Aqua for Multimode OM3/OM4. This helps installers quickly identify the fiber type within the optical fiber cable.

Conclusion

Successfully deploying fiber optics requires understanding the difference between the two core components you are buying. The optical fiber is the delicate glass core responsible for transmitting data as light, while the optical fiber cable is the complex, multi-layered assembly engineered for protection. Always choose a cable structure that meets local fire codes (e.g., Plenum or Riser rated). For high-quality, reliable, and compliant fiber optic cables tailored to every environment, trust PHILISUN.

Ready to find the perfect fiber solution for your next project? Browse PHILISUN’s full range of fiber optic cables and start building a future-proof network today.