The NVIDIA ConnectX-8 SuperNIC: A Technical Deep Dive into the 800Gb/s Cabling Imperative

The pursuit of AI scaling has driven data throughput to unimaginable levels. At the vanguard of this acceleration is the NVIDIA ConnectX-8 (CX8) SuperNIC, the foundational component for the next generation of AI and HPC clusters. The CX8 delivers an astounding 800Gb/s of performance. However, this revolutionary speed is entirely dependent on the flawless transmission of data across its optical interconnects. This analysis explores the stringent cabling demands of the ConnectX-8 and the physical layer engineering required to ensure this 800Gb/s investment is fully realized.

The CX8 Architecture: Defining the 800Gb/s AI SuperNIC

The ConnectX-8 is a highly programmable engine designed to offload data-intensive tasks from the host CPU.

The Role of the CX8 in Accelerated Computing

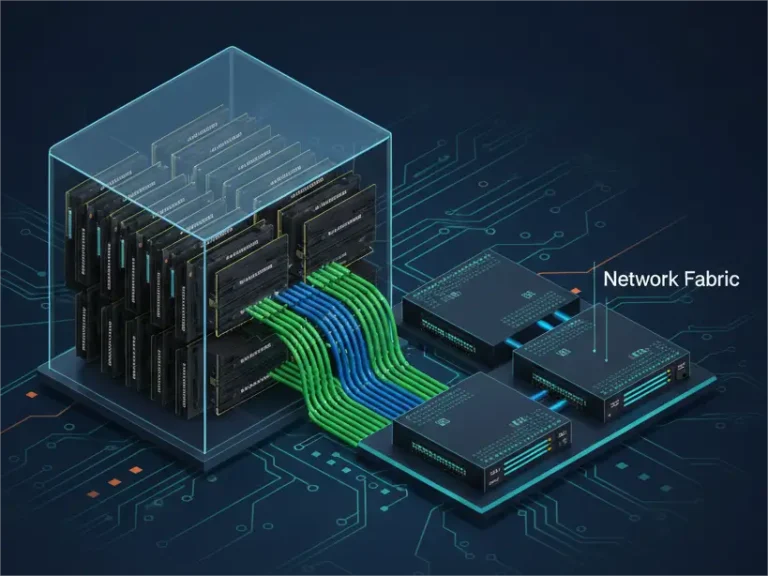

In an NVIDIA accelerated cluster, the CX8 serves as the primary communication gateway, handling the intense data exchange required for training large language models (LLMs) and performing parallel computations across thousands of GPUs. The card maintains crucial Remote Direct Memory Access (RDMA) capabilities, allowing direct memory transfers between devices with near-zero latency and minimal CPU overhead. The ability to sustain ultra-low latency while operating at 800Gb/s is precisely what differentiates an effective AI supercomputer from a collection of powerful, but uncoordinated, servers.

CX8 Feature Deep Dive: In-Network Computing and Sharp

The CX8 integrates advanced In-Network Computing features, such as the NVIDIA SHARP (Scalable Hierarchical Aggregation and Reduction Protocol). SHARP performs data aggregation operations directly within the network switch fabric, reducing latency and increasing effective bandwidth. This capability, however, exponentially increases the sensitivity of the entire network to physical layer errors. A momentary loss of signal integrity due to a poor connector can halt complex, coordinated network operations across the entire cluster.

The Challenge of Physical Layer Interconnection (I/O) at 800 Gb/s

The sheer bandwidth of the CX8 necessitates a paradigm shift in the physical form factors and fiber types used within the data center.

OSFP and QSFP-DD: The 800Gb/s Interface Shift

To achieve 800Gb/s on a single port, the CX8 utilizes high-density transceiver form factors, primarily OSFP (Octal Small Form-factor Pluggable) or QSFP-DD (Quad Small Form-factor Pluggable-Double Density). These interfaces handle up to eight high-speed electrical lanes, each running at 100Gb/s or more. This multiplication of lanes demands perfect synchronization and fidelity for the optical signal that carries the data.

The MPO-16 Imperative

Interfacing with these high-density transceivers requires an evolution of the multi-fiber connector. While older generations used 12-fiber MPO connectors, the CX8’s 800Gb/s connectivity demands MPO-16 or even MPO-32 connectors. The MPO-16 physically aligns 16 fibers simultaneously. This increased fiber count dramatically heightens the risk of misalignment, dust contamination, and cumulative loss, making connector quality the single greatest technical challenge for CX8 deployment.

The Fiber Quality Triangle: Why 800G Performance Rests on Three Metrics

The perfect operation of the ConnectX-8 is governed by three interdependent factors at the fiber connection point:

Insertion Loss

Insertion Loss (IL) is the power loss incurred when light passes through a connector or splice. At 800Gb/s, the optical power budget—the tolerance for IL—is severely limited. Every tenth of a decibel (0.1dB) of unnecessary loss introduced by a poor connector consumes a large percentage of this budget. For high-speed links, a cumulative IL exceeding specification results in a high Bit Error Rate (BER), forcing data retransmission and completely eliminating the ConnectX-8’s latency advantage. Premium suppliers must guarantee insertion loss figures of 0.35dB or less per MPO-16 mating.

Return Loss

Return Loss (RL) measures the amount of light reflected back toward the light source. High RL can introduce noise, destabilize the optical transceiver, and is especially problematic in advanced signaling schemes used at 800G. For ConnectX-8 links, APC (Angled Physical Contact) polishing on connectors is often preferred over UPC (Ultra Physical Contact) because the 8° angle forces reflected light into the fiber cladding, minimizing destructive back-reflection and protecting the sensitive transceivers.

End-Face Geometry

The performance of the MPO-16 connector is determined by the microscopic precision of its end-face geometry. Parameters such as Fiber Height, Radius of Curvature, and Apex Offset must be meticulously controlled. If the fibers in an MPO-16 connector are not perfectly aligned and polished to the nanometer level, the resulting air gap causes high Insertion Loss and destructive back-reflection, instantly destabilizing the 800Gb/s link. This level of precision requires sophisticated factory calibration and quality control.

Active vs. Passive: Cabling Solutions for CX8 Ports

Selecting the right physical cable type is crucial for optimizing the CX8’s performance across varying link distances while managing power consumption.

Direct Attach Copper (DAC)

For very short, intra-rack links (typically 3m), passive DACs are often used for cost and convenience. However, due to significant signal attenuation at 800Gb/s, the maximum reliable distance for DACs is shrinking with each generation, limiting their utility in large-scale AI clusters.

Active Optical Cable (AOC)

Active Optical Cable (AOC)—a core product line for PHILISUN—provides a superior solution for mid-range connectivity (up to 50-100m). AOCs integrate transceivers within the cable ends, simplifying deployment while offering significantly lower power consumption and heat generation compared to using separate optical transceivers. For large-scale AI clusters where power budgets are strictly managed, AOCs connected to the CX8 ports offer an ideal balance of performance and energy efficiency.

Optical Transceivers and Fiber Jumper Assemblies

For longer links—such as inter-rack or facility-wide connections—standard optical transceivers (e.g., 800G OSFP) combined with discrete fiber jumper assemblies are necessary. This requires the use of ultra-low-loss single-mode fiber and certified MPO-16 jumpers to ensure the signal can reach its destination without exceeding the IL budget.

Tier 2 Certification: Guaranteeing the CX8 Investment

The stringent performance requirements of the NVIDIA ConnectX-8 mean that standard, low-cost testing procedures are wholly inadequate.

Why Tier 1 Testing is Insufficient for MPO-16

Tier 1 certification (testing total loss using a light source and power meter) only measures the end-to-end performance and cannot isolate faults. For complex, multi-fiber MPO-16 assemblies destined for CX8 connections, Tier 1 is insufficient because it cannot identify a faulty splice, a micro-bend, or a single poorly polished fiber within the 16-fiber array.

The Necessity of OTDR (Tier 2) Certification

Only Tier 2 certification, utilizing an Optical Time Domain Reflectometer (OTDR), can verify the physical integrity of every component. The OTDR acts as optical radar, mapping the loss characteristics of every meter of fiber, every connector, and every splice. For critical infrastructure supporting 800Gb/s CX8 clusters, PHILISUN guarantees that the delivered assemblies meet the stringent low-loss requirements. This due diligence transforms a cable assembly from a commodity into a certified, high-performance asset.

Conclusion

The NVIDIA ConnectX-8 (CX8) is a technological marvel designed to power the next wave of AI and HPC development. However, deploying an 800Gb/s cluster with sub-standard connectivity is akin to fueling a supercar with low-grade gasoline. The investment in advanced silicon, like the CX8 demands a proportional investment in certified, ultra-low-loss fiber optic infrastructure. By focusing on the Fiber Quality Triangle—minimizing insertion loss, controlling return loss, and ensuring precise MPO-16 geometry—data center operators can unlock the full, intended performance of the CX8 SuperNIC. To safeguard your AI investment and guarantee stable, zero-error 800Gb/s operation, only certified, precision-engineered fiber solutions should be deployed.

Do not let poor cabling bottleneck your 800Gb/s infrastructure.

Frequently Asked Questions (FAQ)

- Q: What speed does the CX8 support?

- A: The CX8 primarily supports data rates up to 800Gb/s (400G per port) using OSFP or QSFP-DD interfaces for AI and HPC clusters.

- Q: What connector type does the CX8 require?

- A: It uses OSFP/QSFP-DD interfaces, which require MPO-16 connectors to physically align the 16 fibers needed for the high-density 800G parallel transmission.

- Q: What is the main cabling challenge at 800 Gb/s?

- A: Managing Insertion Loss (IL). The tight 800G power budget means slight signal loss from connectors can cause high Bit Error Rates and performance failure.

- Q: What is Tier 2 Certification?

- A: It involves OTDR (Optical Time Domain Reflectometer) testing to verify the loss characteristics of every component. This guarantees the ultra-low insertion loss required for stable 800G links.

- Q: When should I choose an AOC over a DAC for CX8?

- A: We recommend AOCs for mid-range links (3m to 100m) because they are more power-efficient than transceivers and maintain low latency better than DACs at 800G.