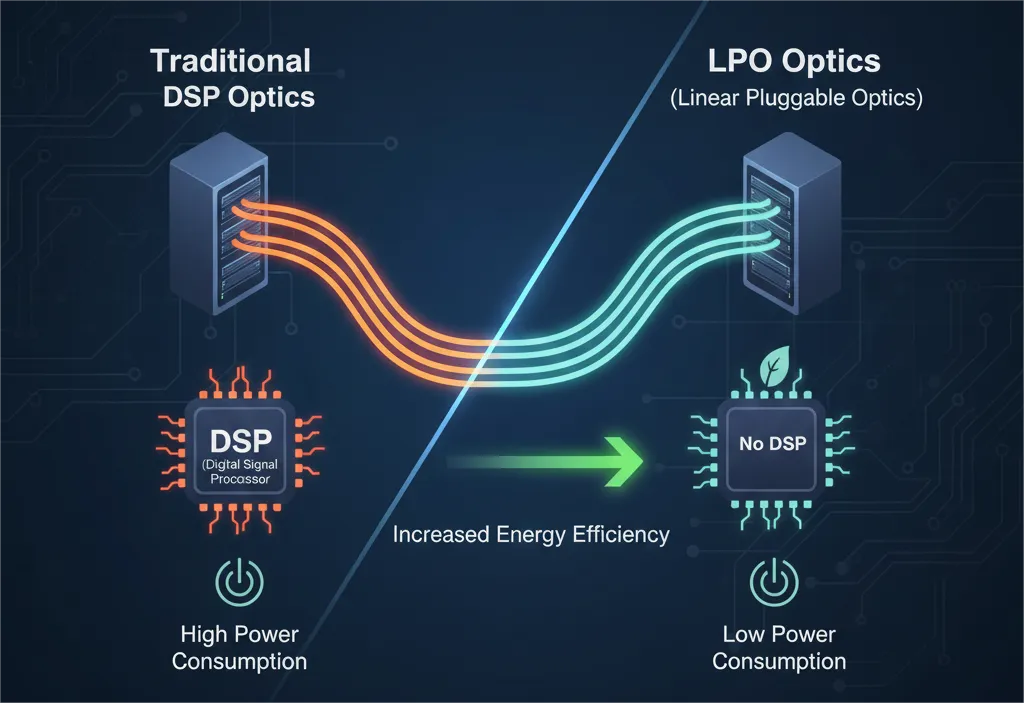

The relentless push toward 800G and 1.6T speeds in the data center has introduced a critical bottleneck: power consumption. Traditional optical transceivers rely on complex Digital Signal Processors (DSPs) to correct signal integrity, but these chips generate significant heat and consume substantial power. LPO Optics (Linear-Drive Pluggable Optics) is an emerging technology designed to address this challenge head-on. By fundamentally redesigning the transceiver to remove the DSP, LPO promises a radical reduction in power draw and latency, positioning itself as a vital component in the architecture of the next generation of energy-efficient AI and hyper-scale fabrics.

Introduction to the DSP Bottleneck

The Digital Signal Processor (DSP) has been essential for enabling high-speed PAM4 signaling, but its necessity comes at a cost that is no longer sustainable.

The Role of the Digital Signal Processor (DSP) in Traditional Optics

In transceivers operating at 400G and above, the DSP performs vital functions: signal equalization, dispersion compensation, and clock recovery. It meticulously cleans up and processes the degraded electrical and optical signals, ensuring they adhere to standards over longer reaches. This complex silicon logic is the engine that drives high-performance optics.

The High Cost of Complexity: Power Draw and Latency

While effective, the DSP is the single largest consumer of power within a traditional transceiver, often accounting for over half of the module’s total thermal budget. This power draw contributes significantly to the operational costs and cooling challenges in high-density switches and racks. Furthermore, the signal processing time introduces measurable latency, which is detrimental to high-performance computing (HPC) and AI/ML traffic.

LPO Mechanism: The Power of Simplicity

LPO Optics achieves its efficiency gains through architectural minimalism, focusing on a direct, linear signal path.

What is Linear-Drive Pluggable Optics (LPO)?

LPO Optics replaces the complex, power-hungry DSP with simpler, high-linearity analog components (Linear Drivers and Transimpedance Amplifiers). These components boost and condition the signal without the heavy computational workload of a DSP. By eliminating the DSP, the power-to-bandwidth ratio is drastically improved. PHILISUN is currently developing LPO-based products aimed at supporting internal data center links up to 800G with minimal energy use.

The Power Savings and Thermal Advantage

LPO transceivers can reduce power consumption by 50% or more compared to their DSP-enabled counterparts. This translates directly into substantial operational savings and a massive reduction in the cooling load placed on the switch and the data center facility. Less heat means higher switch port density and better overall thermal management.

The Latency Advantage: Near-Zero Processing Delay

Because the heavy computational cycle of the DSP is removed, LPO modules transmit data with significantly lower latency. This near-zero processing delay is a critical advantage for time-sensitive applications like distributed memory access, high-frequency trading, and AI inter-GPU communication.

Design Constraints and Industry Challenges

The architectural simplification that powers LPO also introduces specific constraints that impact its deployment.

LPO’s Increased Sensitivity to the Fiber Optic Channel

The most significant constraint of LPO is its reliance on a pristine signal. Since LPO lacks the DSP to correct signal imperfections, it is highly sensitive to the quality of the channel. This requires extremely high-quality, low-loss Single Mode Fiber (SMF) and pre-tested cabling. Deploying LPO successfully often requires upgrading the existing fiber plant to meet stringent insertion loss budgets. PHILISUN‘s expertise in providing ultra low-loss MPO cabling is crucial for achieving reliable LPO performance.

Distance and Reach Limitations Compared to Traditional Optics

Due to the lack of signal correction, LPO is fundamentally a short-reach technology. While DSP optics can handle longer distances within the data center, LPO is generally restricted to intra-rack and short inter-rack connections (e.g., 50 meters or less), making it ideal for access and top-of-rack applications but unsuitable for long-haul Data Center Interconnect (DCI).

Industry Standardization and Interoperability

The technology is still maturing, leading to ongoing discussions within industry groups like the OIF regarding standardization and interoperability. Establishing uniform specifications is key to mass adoption and ensuring that LPO modules from different vendors can seamlessly work together.

Conclusion

LPO Optics represents a major inflection point, trading maximum reach for extreme power efficiency and ultra-low latency. While its application is restricted to shorter links, its potential to drastically reduce the energy footprint of 800G and future AI fabrics makes it a critical technology for enterprise scalability.

To learn more about our innovative fiber optic technologies and high-speed networking solutions, contact PHILISUN Experts Today.

Frequently Asked Questions (FAQ)

Q1: What is the primary function of LPO?

A1: To reduce power consumption and latency by removing the Digital Signal Processor (DSP) from the optical transceiver.

Q2: How much power can LPO save?

A2: LPO can save 50% or more power compared to traditional DSP-based pluggable optics.

Q3: Is LPO a long-distance technology?

A3: No. Due to the lack of signal correction, LPO is currently limited to very short reaches (e.g., intra-rack) and requires high-quality fiber.

Q4: What is the main trade-off when using LPO?

A4: The trade-off is sacrificing distance (reach) for massive power savings and latency reduction.

Q5: What kind of fiber is best suited for LPO?

A5: High-quality, low-attenuation Single Mode Fiber (OS2) is typically required to maintain signal integrity without DSP correction.