While the modern data center demands high-density connectors like the LC, the venerable ST connector remains essential in specialized fields. Its survival is due to one unique feature: its sheer physical durability and robust bayonet locking mechanism. For fiber optic connectors deployed in harsh industrial environments, military systems, or legacy networks, the ST provides unmatched resilience to vibration and physical stress. This analysis explains the technical mechanics of the ST connector’s design and outlines its specific commercial niche where reliability is more valuable than port density.

What Is an ST Fiber Optic Connector

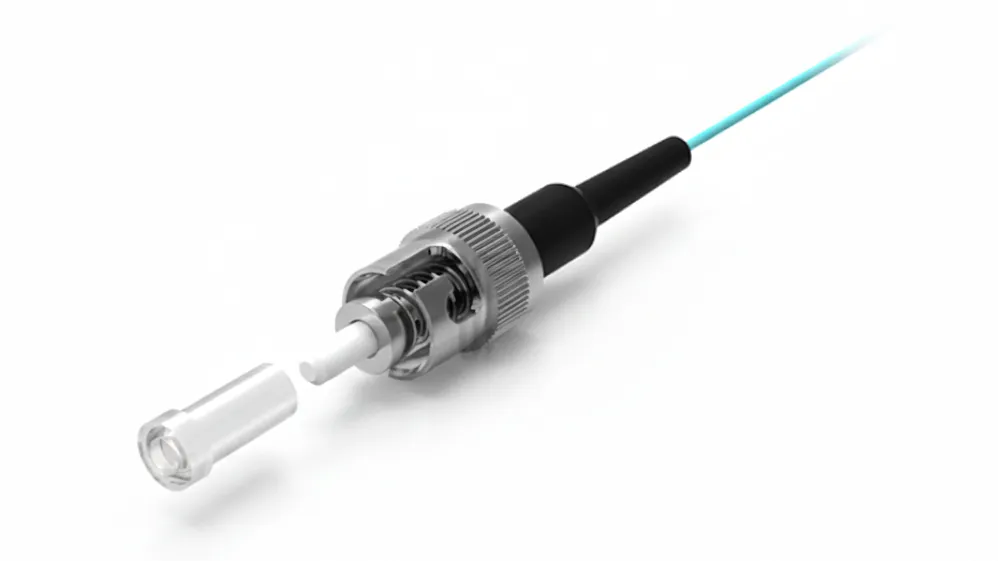

The ST connector is characterized by its legacy size and its robust, quarter-turn mechanical locking feature, which pioneered the era of low-loss fiber connectivity.

The 2.5mm Ferrule: Historical Context and Low-Loss Prowess

The ST connector was a market leader because it introduced two major technical improvements over its predecessors (like the SMA connector): the use of a ceramic ferrule and a keyed connection. Its core component is a precise 2.5mm ceramic ferrule—a large diameter standard that later influenced the design of the SC connector. The ceramic material offered far superior thermal stability and dimensional accuracy compared to earlier metal or plastic ferrules, resulting in significantly improved, repeatable performance and very low Insertion Loss (IL). The wide adoption of the ST connector solidified the 2.5mm ferrule as the industry standard for over a decade.

The Keyed Bayonet Coupling: A Direct Investment in Durability

The defining and enduring feature of the ST connector is its spring-loaded, keyed bayonet coupling mechanism. This requires the connector to be inserted and twisted approximately 45 degrees, locking it securely into place. This design provides immediate commercial advantages for demanding installations:

- Vibration Resistance: The constant rotational pressure of the spring ensures the ferrule tips remain firmly pressed together, maintaining optical alignment even when subjected to intense, continuous vibration (e.g., train transit, factory machinery).

- Mechanical Strength: The bayonet coupling acts as a superior mechanical clamp, distributing physical stress better than simple push-pull designs.

- Repeatability and MTBF: The integrated key ensures that the connection always seats in the same angular orientation, which maximizes physical contact consistency, leading to lower maintenance costs and a higher Mean Time Between Failures (MTBF) in harsh environments.

The ST Connector’s Strategic Commercial Niche

The continued demand for the ST connector proves that in many specialized sectors, durability and connection integrity outweigh the need for high port density.

Resilience in Highly Volatile and Industrial Environments

The ST connector is highly favored in commercial environments where the fiber run is exposed to severe environmental or mechanical stress. Procurement managers specify the ST connector for these critical installations because reliability is non-negotiable:

- Industrial Automation (Factory Floor): Used extensively for connecting sensors, Programmable Logic Controllers (PLCs), and control systems where heavy machinery causes constant floor vibration and shock.

- Military and Field Communications: Ideal for deployable systems where ruggedness and simple field termination are required.

- Oil and Gas Infrastructure: Provides reliable connectivity in field cabinets subject to temperature swings and movement.

PHILISUN specifically addresses this market by supplying high-performance ST connector assemblies manufactured with high-grade ceramic ferrules to maximize durability in these challenging sectors.

Supporting the Vast Legacy Installed Base

The sheer number of installed ST fiber optic panels and equipment globally mandates its continued use. Enterprises running older LANs, data center peripherals, and specialized telecommunication equipment (like early SONET systems) rely on ST patch cables for maintenance and basic expansion. The cost of replacing an entire infrastructure of ST patch panels and media converters often exceeds the cost of purchasing new ST-to-LC hybrid cables, maintaining the commercial necessity of the ST standard.

Technical Trade-offs and Modern Comparison

To fully understand the ST connector’s commercial standing, one must assess the technical trade-off it demands: ruggedness for density.

Simplex Configuration and Performance Metrics

The ST connector is fundamentally a Simplex connector, meaning it carries a single fiber strand. While it is possible to clip two connectors together for Duplex communication, this often creates a cumbersome, large assembly. Technically, when properly terminated and cleaned, ST connectors provide excellent performance metrics suitable for Multimode applications, typically achieving:

- Insertion Loss (IL): Routinely less than 0.3 dB per mated pair.

- Polish: Typically uses the UPC (Ultra Physical Contact) polish to ensure good Return Loss figures.

The Density Trade-off: Why Modern Switches Exclude ST

The main technical hurdle that led to the decline of the ST in core networking is its size. The 2.5mm ferrule and bulky bayonet housing consume significant panel space. To illustrate the commercial impact:

- A standard 1U patch panel can typically house 24 ST ports.

- The same 1U panel can house 48 SC ports or up to 96 LC ports.

This severe limitation on port density makes the ST connector non-viable for modern data center switches and routers, where maximizing bandwidth per rack unit is the primary objective. However, where physical access and connection stability are the defining factors—such as remote industrial sites—the density trade-off is easily justified. PHILISUN continues to offer high-quality ST connector products to support the maintenance and expansion of these high-reliability, low-density network environments.

Conclusion

The ST connector’s enduring presence in fiber optic networks is a strategic commercial choice driven by mechanical superiority rather than bandwidth or density. Its robust, bayonet locking mechanism offers unmatched resilience to vibration and physical stress, making it the preferred, cost-effective fiber optic connectors solution for industrial, military, and long-standing legacy systems where rugged reliability trumps port density.

For rugged, reliable fiber optic connectors and patch panels tailored for industrial and legacy network environments, explore PHILISUN’s Complete Fiber Solutions today.

Frequently Asked Questions (FAQ)

Q1: What does ST stand for?

A1: ST stands for Straight Tip, referring to its cylindrical shape.

Q2: What is the locking mechanism of the ST connector?

A2: It uses a spring-loaded, keyed bayonet twist-and-lock mechanism.

Q3: What size ferrule does the ST connector use?

A3: It uses the large, industry-standard 2.5mm ceramic ferrule.

Q4: Where are ST connectors still primarily used?

A4: They are primarily used in industrial control systems, military field communication, and older enterprise systems. These scenarios require high physical durability and vibration resistance.

Q5: Why did the industry move away from the ST connector?

A5: The industry moved away due to its low port density compared to smaller connectors like the SC and the LC. The LC connectors offer a higher fiber count per rack unit.